CODICO - Automated Small Parts Warehouse

Docked

CODICO distributes high-quality electronic construction components which are also developed individually for customers if needed. Since its formation in 1977, the Perchtoldsdorf-based company has been marked by a constant growth trend. In the years that have followed, it has seen expansions, moves and reconstructions. However, logistics could no longer keep pace with the pleasing development of the core business. The management decided to revitalize its logistics and mandated Xvise to work out possible scenarios for expanding the site.

New annexed building

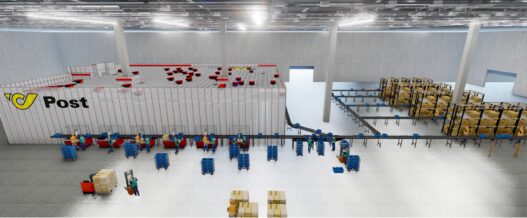

After an extensive scenario development, we accompanied the ultimate preferred scenario in its implementation. The core of the concept involved a new logistics building housing the incoming and outgoing goods departments. The existing building was opened at the side and the expansion building was annexed to it. Additionally, we planned an efficient, fully automatic small parts warehouse to replace the previous small parts storage area. The space in the old stock area created by this would be used for an expansion of the existing pallet warehouse.

Efficient small parts handling

Incoming goods has a so-called deconsolidation area. There, the goods that arrive in pallets or boxes are taken on, transferred, and brought into the small parts warehouse in an automated manner. In picking, each item is transferred either directly to the packaging area or to the picking station, put into target containers, and transported on to the packing station – again in an automated manner. There, employees finally put together the materials from the pallet and small parts warehouse and get them ready for shipping. A new warehouse management system ensures that the different items included in an order come together without time loss and also ensures exact traceability of the goods. Since the CODICO components are used both in medical engineering and in sophisticated industrial applications, the requirements in relation to transparent goods and data flows are correspondingly high.

We were also responsible for the concept planning of the buildings as well as the loading yard on which the architect had set up. We were thus continuously in coordination during the planning and construction work. Additionally, we assumed the tender of the small parts warehouse, the forklift fleet, the packing stations and the pallet warehouse. The continual project management was completed by accompanying the implementation and start of operational processing.