Site Planning for Gebrüder Weiss Wolfurt

A new build designed for the future

Gebrüder Weiss needs space. Not only for its growing warehousing and logistics business, but also its own IT department. A new IT and logistics center, ideally located at the Wolfurt Freight Centre, has been designed to provide outstanding benefits for customers and employees alike. Our parent group entrusted us with the location planning.

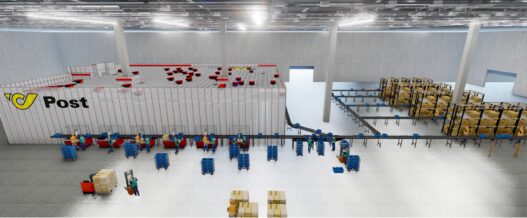

Automatic vs. manual warehouse processing

We started by determining which processing options could be used at the new location based on the company’s required capacities and inbound and outbound services. We needed to know precisely how customer orders would be processed at the site. Due to the high capacity requirements, it quickly became apparent that the only feasible option would be automatic warehouse processing; the space needed for manual processing with forklifts simply wasn’t available in the region.

We then assessed the capacities required with the corresponding loading equipment, the inbound, picking and outbound services, and the respective space required for these. The next steps were to find the appropriate warehouse processing technologies, create warehouse layouts and material flow plans, design the corresponding processes, and calculate budget costs. After comparing and assessing the solutions we developed, GW decided which version to implement.

We were then tasked with the detailed planning of the warehouse equipment. The shelving system is designed for Euro and industrial pallets, with 13 aisles of double-depth racks. The warehouse equipment includes 13 stacker cranes, conveyor systems, eight picking stations based on the goods-to-person principle, empty pallet stacking and unstacking stations, and automatic strapping, pallet wrapping and labeling. Finally, we created the Statement of Work for tendering out the logistics components, carried out the tender, and guided GW with awarding the work.

Vendor agnostic solution development

We remained in close contact with all the GW staff involved throughout the entire duration of the project. We were able to use our extensive experience in location planning and identify potential stumbling blocks. Meanwhile, Gebrüder Weiss was able to rely on vendor agnostic solution development for its future logistics center.

The building process is expected to last until late 2025, resulting in the creation of a 34-meter-tall high-bay warehouse with 68,000 pallet spaces. By mid-2026, this will be joined by a 4,500 m2 logistics warehouse, topped with a three-story office building for 350 employees. We are delighted that this project has given us the opportunity to use our expertise in warehouse automation to design the GW Corporate Group’s first automatic high-bay pallet warehouse.